Timed Automatic Sootblower

The exclusive Cain Industries Timed Automatic Sootblower design is applied where the sulphur content is high and/or combustion efficiency is poor. When a soot layer accumulates on the heating surface to a thickness of 1/8", fuel consumption is increased by 8.5%. The sootblower is also applied when it is not cost-effective to open inspection doors and clean the exchanger by other means. The sootblower system will continually keep the heating surface at a high performance level and eliminate the day-to-day operator expense and operation down time.

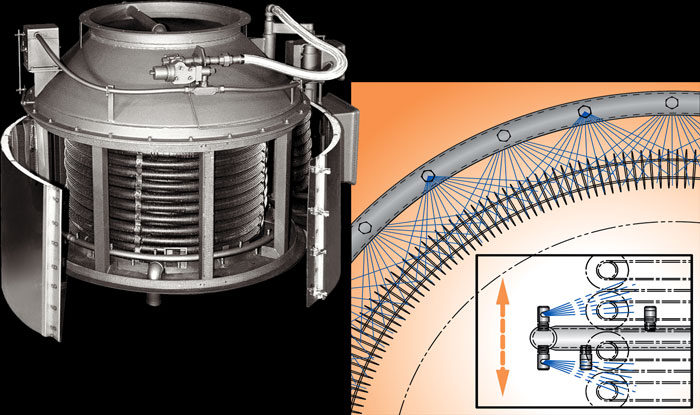

The blowdown sequence occurs while the boiler is in full operation and is fully adjustable. The special flood-jet type nozzles achieve maximum cleaning velocity using steam or air as discharged through an electric control valve.

Together they form a “continuous knife edge concentrated spray pattern” surrounding the heating surface. This “ring nozzle assembly” is attached to a manifolded flexible steel hose assembly and powered up and down by a pneumatic drive cylinder. Dual timing relays allow complete control for cycle duration and interval specific to each application. The final results are a controlled double cleaning action, insuring that the maximum BTU recovery and anticipated savings are achieved.

Available for Boiler Economizer Series:

FCR | RTR | B Series

Available for Gas & Diesel Cogeneration Series:

ESG1 | HRSR | UTR1